The Process of Applying Spray Foam: What You Need to Know

The Process of Applying Spray Foam: What You Need to Know

Blog Article

Spray Foam: The Ultimate Solution for Air Sealing and Insulation

Spray foam insulation has arised as a leading remedy for effective air securing and thermal insulation, providing an one-of-a-kind combination of homes that set it apart from traditional methods. Recognizing the full range of its benefits, installation processes, and comparisons with other insulation types is important for making notified choices.

What Is Spray Foam?

Spray foam is a functional insulation material that combines the principles of air securing and thermal resistance to boost energy performance in buildings. Made up mostly of polyurethane or other similar substances, spray foam is used as a liquid that increases upon contact with surfaces, developing a solid, continual layer of insulation. This special home allows it to fill up gaps, fractures, and spaces that conventional insulation products might ignore, providing a remarkable air seal.

There are two primary sorts of spray foam: open-cell and closed-cell. Open-cell spray foam is lighter and much more versatile, using outstanding audio absorption and a reduced R-value per inch - Spray Foam. In contrast, closed-cell spray foam is denser, offering a higher R-value, moisture resistance, and added structural integrity to building elements

The application procedure normally entails specific tools, ensuring a seamless application that complies with various substratums, consisting of metal, wood, and concrete. This flexibility makes spray foam appropriate for both brand-new building and constructions and retrofitting existing frameworks. Its capacity to create an impermeable barrier dramatically adds to decreasing power consumption and enhancing interior air top quality, therefore making it a preferred selection among homeowners and home builders alike.

Benefits of Spray Foam Insulation

Among the most substantial advantages of spray foam insulation is its outstanding capability to create a continuous air obstacle, which properly decreases power loss. Unlike typical insulation materials, spray foam expands to fill up spaces and splits, guaranteeing that air leak is substantially decreased. This characteristic not only improves power performance but likewise results in reduce energy bills in time.

In addition, spray foam insulation offers remarkable thermal resistance, contributing to a much more stable interior setting. Its high R-value per inch enables for efficient insulation in constrained rooms, making it suitable for attic rooms, walls, and crawl spaces. The moisture-resistant residential or commercial properties of spray foam aid stop mold and mildew and mildew growth, promoting healthier living problems.

Another essential benefit of spray foam insulation is its sound-dampening qualities (Spray Foam). It successfully lowers noise transmission in between spaces, creating a quieter and much more comfy home environment. The longevity of spray foam also stands apart, as it does not sag or work out with time, keeping its efficiency throughout its life expectancy

How Spray Foam Works

Comprehending exactly how spray foam insulation works is essential for valuing its effectiveness in air securing and thermal resistance. Spray foam insulation includes 2 primary parts: isocyanate and polyol material. When these parts are combined, they go through a chemical response that triggers the product to broaden swiftly, developing a thick foam that fills dental caries, gaps, and cracks.

As the foam broadens, it sticks to surface areas, developing a closed seal that considerably decreases air seepage. This characteristic makes spray foam insulation highly efficient at preventing drafts and wetness penetration, which can bring about power loss and damages in time. Additionally, the closed-cell variation of spray foam uses exceptional thermal resistance because of its rigid framework, successfully lessening heat transfer.

The special residential properties of spray foam enable it to adjust to irregular surface areas, ensuring thorough coverage and a seamless obstacle. As an outcome, spray foam insulation not only improves power efficiency but likewise adds to boosted interior air quality by lowering the accumulation of allergens and toxins. Inevitably, comprehending the technicians behind spray foam highlights its duty as an exceptional selection for insulation and air sealing in both commercial and property applications.

Setup Refine Overview

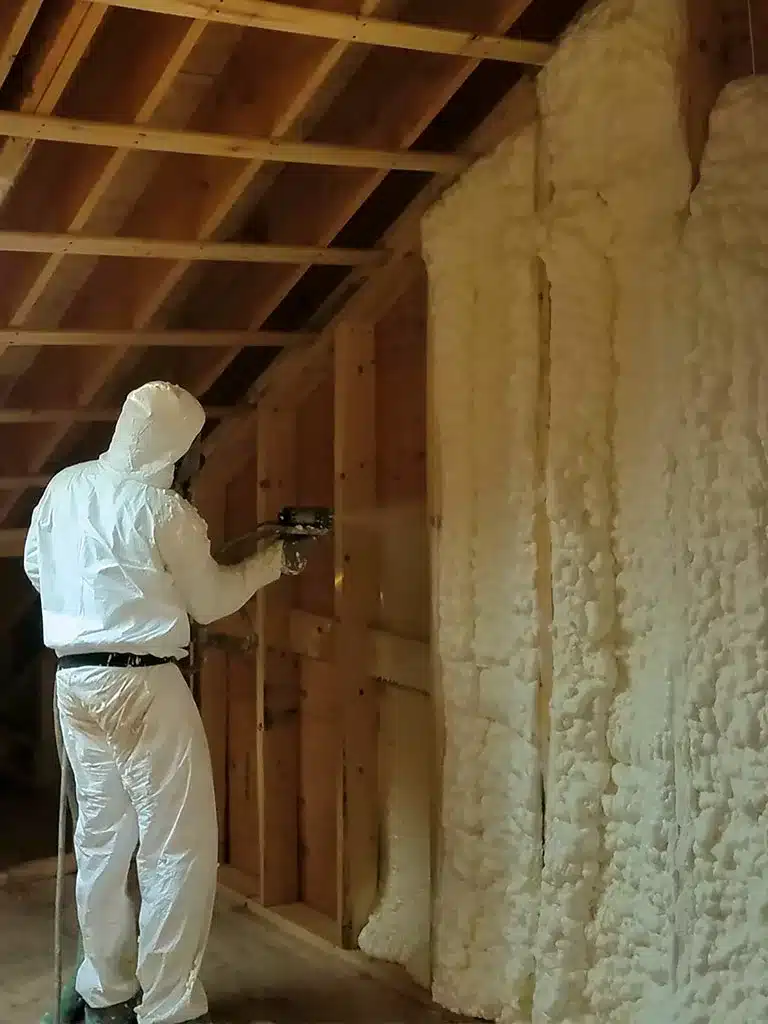

Prior to installment, the room must be appropriately cleaned and prepped, ensuring that surface areas are totally free from dirt, particles, and moisture. This step is vital since impurities can endanger bond and overall efficiency. When the location is prepared, the application involves mixing both components of the spray foam, which increases upon contact and fills voids successfully.

Trained experts must conduct the installation, using specific devices to make certain uniform insurance coverage and optimal thickness. Security precautions, consisting of putting on safety gear and making sure appropriate air flow, are imperative during this procedure. After application, the foam typically treatments quickly, creating a strong obstacle that boosts power performance.

Contrasting Spray Foam to Standard Insulation

When assessing insulation choices, spray foam insulation sticks out in comparison to conventional materials such as fiberglass and cellulose. Among the main advantages of spray foam is its exceptional air securing capabilities. Unlike fiberglass and cellulose, which can allow air infiltration, spray foam increases upon application, filling up crevices and gaps to develop a closed seal. This causes boosted power efficiency, as much less warmed or cooled down air escapes the home, bring about lower utility bills.

In addition, spray foam supplies a greater R-value per inch than standard insulation kinds, providing even more effective thermal resistance in a thinner profile. This particular is especially valuable in areas with minimal cavity deepness. Spray foam is immune to dampness and page mold growth, which can be a significant issue with cellulose and fiberglass, specifically in humid atmospheres.

Nonetheless, spray foam insulation usually lugs a higher in advance cost than its standard counterparts. Homeowners should evaluate this initial financial investment versus long-term energy savings and efficiency advantages. Ultimately, while both insulation types offer try this out their function, spray foam becomes a much more innovative solution for modern insulation needs, especially in regards to air sealing and thermal efficiency.

Conclusion

In recap, spray foam insulation stands for a very efficient service for accomplishing optimum air sealing and thermal resistance. Its special homes, consisting of wetness resistance and noise dampening, make it ideal for numerous applications in both brand-new buildings and retrofitting projects (Spray Foam). The first expenses might be greater compared to conventional insulation products, the lasting benefits, such as substantial energy financial savings and improved interior air top quality, justify the investment and emphasize its worth in contemporary building methods.

Spray foam insulation has arised as a leading service for reliable air securing and thermal insulation, providing a distinct mix of homes that establish it apart from standard approaches.Spray foam is a flexible insulation product that integrates the principles of air securing and thermal resistance to improve Look At This power efficiency in buildings.When evaluating insulation alternatives, spray foam insulation stands out in comparison to standard materials such as fiberglass and cellulose. Eventually, while both insulation kinds serve their function, spray foam arises as a much more sophisticated remedy for modern insulation requirements, specifically in terms of air sealing and thermal performance.

In summary, spray foam insulation represents a very efficient solution for accomplishing optimal air sealing and thermal resistance.

Report this page